ABOUT US

Chronicle

Company’s Foundation by Julius Montz

Julius MONTZ took over the Mewis coppersmith shop in Heiligenstrasse 30 in Hilden on November 1st, 1911, thereby laying the cornerstone of Julius MONTZ GmbH. The crafts business, founded in 1845, was in bad financial shape. The company chronicle, leather-bound and composed of large hand-written notes, remarks about the first year of the young enterprise: „...the proceeds are barely enough to pay the rent.“ MONTZ saw no option but to accept any and all possible order. He repaired pumps, laid water pipes and carried out repair works. The first major order from the Friedrich Krupp Company in Essen provided the turning point for the entrepreneur. His small company began to blossom in the following years and he soon started to hire apprentices and journeymen. However, the outbreak of the First World War interrupted the so far pleasant development of the small company. Julius MONTZ, now in the of age 46, was temporarily drafted into the Navy. Also, the prohibition to process copper for civil purposes threatened the economic existence of his company. But the production of pots for army field kitchens as well as iron coffee water cookers for the Krupp Company enabled MONTZ to steer his company through the crisis. He again changed his production setup after the war to the processing of aluminium for can production. This allowed him to keep his company running without downsizing.

Starting Over After the Great Inflation

The relief to have made it through the war without serious losses did not last long. Following an illusory boom of the German economy, the runaway inflation soon caused major difficulties. Company MONTZ was not excluded therefrom and bled out financially.

In 1924, all that Julius MONTZ still owned was the property in Heiligenstrasse 30. At this time, the company primarily manufactured devices for fruit and jam processors as well as cupreous containers and appliances for various industries.

Julius Montz – About the Person

Julius MONTZ, son of merchant Casimir MONTZ and his wife Sophie, was born on 28th of September 1870. His older brother Otto early passed away from typhoid fever. After graduating from school, he joined coppersmith Timpop in Hagen as an apprentice. It is reported that he assured his listeners that, in his four years as an apprentice, he had probably learned to push a trolley around but that he had not worked on a sheet of copper at all. Therefore, he concluded that he should become a journeyman after the conclusion of his apprenticeship; such journeys were quite common at that time. The chronic reflects: “These journeys and the work in the many workshops which produced a variety of products, not only conveyed excellent professional expertise to the young copper smith, but also enabled him to get to know the country and its people”. He was infected with the travel bug.

At the age of 22, Julius MONTZ was conscripted into the Navy where he was promoted to Feuermeister mate over the years. He is reported to have been raving with his apprentices about his two extended international voyages on the cadet ship “Stein“ for many years after a hard day’s work. Following a side-trip to the USA, he arrived in the Sauerland city of Neheim around 1896 and was hired there in a large coppersmith shop. This is where he met his soon-to-be wife Hedwig Schur. But before they were married in 1900, MONTZ first spent some time in Italy where he fitted carbonization plants for the Neheim company. Upon his return, he was promoted to foreman.

In 1902, the young family which soon after the wedding were having the children Walter, Otto and Else, moved to Gelsenkirchen. Julius MONTZ had been hired by the Gelsenkirchen company Küppersbusch & Söhne. In 1909, he founded his first own company jointly with Theodor Blaché in Siegen. However, the ideas of the two founders were not matching well, leading MONTZ to accept Fritz Mewis’ offer to purchase Mewis’ economically ailing coppersmith shop in Hilden already two years later.

The original plan was that his eldest son Walter was to take over the company one day but Walter already passed away at the young age of 21. Therefore, he transferred the company management to his son Otto in 1925.

Julius MONTZ remained strongly linked to this company and his workforce until his death on May 4, 1954. The last entry in the hand-written chronicle is a congratulation of the workforce to his 80th birthday. In the obituary for his father, Otto MONTZ wrote: “The spirit of this splendid man who demanded so little for himself and who received so much admiration and love just because of that, shall be legacy and obligation for my employees and for myself for the future.“

Specialization under Otto Montz

Under these threatening economic circumstances, the MONTZ family closed ranks even further. While daughter Else served her father as accountant and “coordinating power“ for many years, son Otto had first planned to become a teacher and to study economic geography and national economy. Now he decided to also join the company and took over the company management in 1925. It was him who convinced Julius MONTZ to specialize in the manufacturing of cupreous boilers.

A commemorative Festschrift at the occasion of the company’s 50th anniversary in 1961 writes: “After his induction, he knew how to convince his father that a high effectiveness in new times could only be achieved through the restriction of the fabrication program, and that the old crafts expertise had to be complemented by scientific theoretical research. For this reason, the workforce was supplemented by experts who had undergone the required engineering training.“ The specialization was a far-sighted decision which was ahead of its time by decades. At first, sales increased continuously; the best seller at that time were cupreous boilers, which were already exported to The Netherlands and to Finland. But the miserable economic situation during the last years of the Weimar Republic and during the first years under der Nazi dictatorship led to a renewed decline for the MONTZ Company.

The prohibition of cupreous boiler production in 1935 was very hard for company MONTZ because their production accounted for about 80 per cent of the total production at that time. For company management and workforce, this meant that they again had to adjust to a whole new market from one day to the next. They decided to now produce iron water tanks for express train wagons, piping systems and iron autoclaves as well as containers, condensers and piping systems for the chemical industry.

Expansion during World War II

In the early 1940s, MONTZ rented a second workshop for aluminium processing at Walder Strasse 14a and purchased premises in Hofstrasse. The move to these premises however was delayed due to the outbreak of the war. In 1939, engineer Werner Cramer joined the quick-growing company as factory manager to support Otto MONTZ. On 30th November 1941, he married Otto MONTZ‘ sister Else and was given procuration.

In 1941, an open crane system was built in a closed hall to create additional production space. Two years later, the company purchased an additional premise at Hofstrasse from company Henkel & Cie. The new building and relocation of the company however were a long time in the coming.

In 1944, two temporary houses with two apartments each were built on this real estate. On 1 January of the same year, the sole proprietorship was converted into a limited commercial partnership. The war was over for the people of Hilden already on April 16, 1945. The Americans moved into the undestroyed city without any fights. At this time, company MONTZ had about 78 employees. During the entire time of belligerent conflicts, the company fortunately was spared bombardments and other war damages. “ We worked until it was no longer feasible. Even in February 1945, we had a goods issue of more than RM 70.000“, as chronicled in neat handwriting.

Already on 15 May of the same year, the company was able to resume production with a severely reduced workforce of twelve employees. In the years following the war, production focused on plants for yeast fabrication and marmelade industry. The dyeworks also located in Hofstrasse were supplied with gigantic containers.

An additional pillar of course was the repair and maintenance of existing facilities. However, the chemical industry again ranked among the best customers. At the time, production was primarily limited in raw materials such as coal and gas as well as transport media and semi-finished products. It was the monetary reform and the introduction of the Deutsch Mark on 20 June 1948 which created an economic recovery with production increases throughout Germany in a very short time. The economic miracle was on the horizon.

Moving to a new Production Site

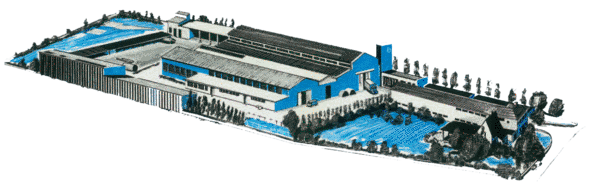

Four years later, in 1952, the long-planned new construction in Hofstrasse began. Already shortly after completion, another expansion became necessary because the company grew continuously.

At that time, there were hardly any buildings immediately adjacent to the new production site. The thick of green trees, hedges and shrubs in the vicinity as well as the villa of the founding family at the entrance to the company premises left the observer with the impression of a private property, rather than a production site.

Both former sites in Heiligenstrasse and Walderstrasse were relinquished in favor of the new company premises. Company founder Julius MONTZ passed away shortly after the move on 4 May 1954 at the age of 83.

Increase of Collaboration with the Chemical Industry

Based on the fruitful collaboration with the chemical industry, Otto MONTZ pushed for a stronger specialization on distillation technology during the 1950s. At the same time, he increased his search for professional discourse and lobbied for his industry sector’s interests with the German Engineering Federation (Verband Deutscher Maschinen- und Anlagenbauer, VDMA).

He was present already during the founding meeting of the Specialist Department 6 on 19 September 1949 and was elected to the board. In 1964, he became chairman of the Specialist Department Apparatus Engineering and member of the VDMA executive board.

A year later, he became the first president of the Gesellschaft for Chemische Technik and Biotechnologie (DECHEMA); in the following year, he became Honorary Senator of the Technical University Munich. Further, Otto MONTZ was a member of Hildener Industrieverein and served as its chairman for several years.

New Countries – New Owners

Already in the 1960s, company MONTZ held numerous patents, among them for the THORMANN®-tray, the STREUBER-tray (tunnel tray), the Kloß-Feder column and the Neo-Kloß- fabric packing column. Up until today, the THORMANN® tray and the tunnel tray are part of the product spectrum. These are trays for wash processes and vacuum distillation. The THORMANN® tray is capable to process smallest amounts of liquid of e.g. 40 liters per square meter per hour, at a minimal pressure loss of just a few mbar per tray.

From the beginning, company MONTZ was strongly oriented towards international business; thus, it is not surprising that a large number of plants in many countries of the world were equipped with MONTZ components already in the early 1960s. Otto MONTZ had no offspring; therefore he sold his company with a heavy heart in 1966 to the Düsseldorf-based Schiess AG. “The separation from company Julius MONTZ GmbH [...] weighed on him heavily“, it is reported in an obituary for Otto MONTZ in March 1978. Up until 1970 – almost the whole time when the company belonged to the Schiess AG –Otto MONTZ stood by “his” company as a consultant.

Sold to Koch-Glitsch

2019 Montz was purchased by Koch-Glitsch, a complete solutions provider and global leader in mass transfer and separations equipment for the chemical, petrochemical, refining, gas processing, pharmaceutical and specialty industries.

Today Julius Montz GmbH has a leading position in its sector. It can offer a comprehensive and efficient range of products and services and is involved in research projects and intensive product developments with leading universities. Thanks to its creative and tailor-made products and services, Montz is a competent and innovative partner for its customers.

MONTZ ENGINEERED COLUMN SYSTEMS

Address:

Hofstraße 82

40723 Hilden

P.O. Box:

P.O. Box 530

40705 Hilden

Telephone: +49 (0) 2103 - 894-0

Fax: +49 (0) 2103 - 894-77

E-mail:

hilden@montz.de

Process technology and plant engineering Landau

Address:

Werner-Heisenberg-Straße 13

76829 Landau

Telephone: +49 (0) 6341 - 5101 - 35

E-mail:

landau@montz-landau.de

MONTZ

| IMPRINT | DATA PROTECTION | CONTACT |

DOWNLOADS | AGB |

AEB

|

Koch-Glitsch |

Koch Privacy Policy |