TYP MN

MONTZ High Performance Packing - Type MN

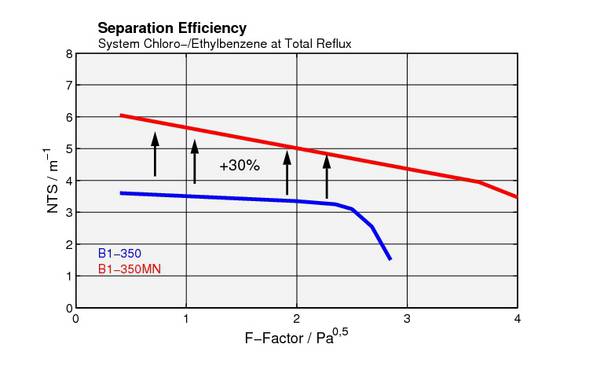

Separation Performance Increase of 30%

The properties and areas of applications of the high performance packings Type MN and M are not fundamentally different from standard packings. Established operational experiences and areas of applications remain valid.

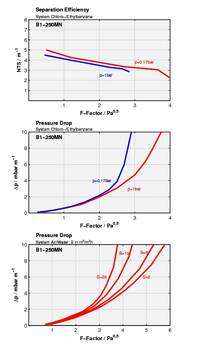

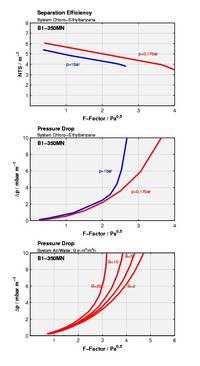

Example of the separation performance advantage for Montz-Pak B1-350MN and B-350 System chlorobenzene / ethyl benzene for total reflux

Separation steps:

- Depending on type, >8 theoretical separation steps per meter are achieved.

Properties:

- Increased throughput capacity

- High flexibility

- High separation performance, close to capacity limits

- Liquid loads from 0.1 up to more than 250 m³/(m² h)

Column data:

- Diameter from 40 mm up to 10 m and wider

- Liquid load from 100 l/(m² h)

- Operating pressures from vacuum up to more than 100 bar

- Minimum liquid hold-up

Applications:

- Vacuum columns

- Atmospheric columns and high pressure columns

- Absorption of components and contaminants from gas flows and air flows

- Natural gas drying with glycols

- Refinery columns (atmospheric and under vacuum)

- Petrochemical columns

- Exhaust air decontamination in Aluminium rolling mills

- Lubricating oil and rolling oil processing

- Waste water stripper

- Retrofit of existing plate columns or packed columns for performance improvement

Assembly:

- Packing layers are manufactured individually or in segments. Packing installation is done through column shell flanges or manholes, as desired.

Materials:

- Stainless steels such as 1.4000, 1.4301, 1.4404, 1.4571, 1.4435, 1.4539 and others

- C-steel

- Hastelloy C4, C22, C276, etc.

- Aluminium, Copper, Titanium, Monel, Tantallum, etc.

- Additional materials are available upon request

MONTZ ENGINEERED COLUMN SYSTEMS

Address:

Hofstraße 82

40723 Hilden

P.O. Box:

P.O. Box 530

40705 Hilden

Telephone: +49 (0) 2103 - 894-0

Fax: +49 (0) 2103 - 894-77

E-mail:

hilden@montz.de

Process technology and plant engineering Landau

Address:

Werner-Heisenberg-Straße 13

76829 Landau

Telephone: +49 (0) 6341 - 5101 - 35

E-mail:

landau@montz-landau.de

MONTZ

| IMPRINT | DATA PROTECTION | CONTACT |

DOWNLOADS | AGB |

AEB

|

Koch-Glitsch |

Koch Privacy Policy |