MONTZ Dividing Wall Columns

Separation technology on the rise

For more than 20 years, dividing wall columns are used in the chemical industry. MONTZ delivered the first dividing wall column and has continuously improved the dividing wall column technology ever since.

With more than 120 dividing wall columns, MONTZ is the leading global provider of this column system.

Dividing wall columns

- Dividing wall columns can be used anywere when complex mixtures are to be split into pure fractions. It is particularly advantageous for the production of pure mid-boiling fractions.

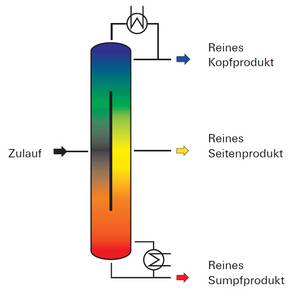

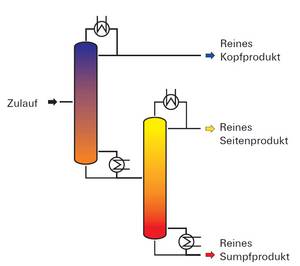

- The separation of a ternary mixture into pure constituents with conventional columns requires a sequential circuit of two columns or a configuration of main columns with side columns. Using a dividing wall column, this task can be achieved in a single distillation column.

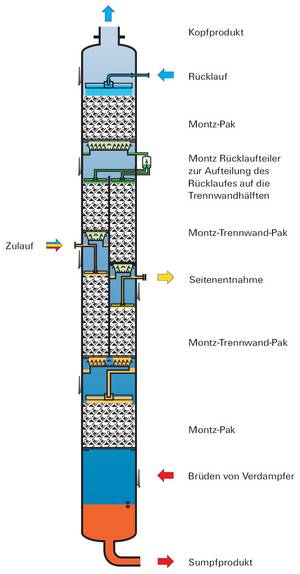

- In dividing wall columns, a vertical wall is positioned in the center part of the column shell. The divided wall separates thefeeding section from the draw-off section. The gas-tight and liquid-tight separation wall enables an energy efficient separation of low boiling and heavy boiling constituents in the feeding section working as a pre-fractionator. The draw-off section is designed for purification of the mid-boiling species.

- Such setup saves a second column for purification of the mid-boiling fraction. Column shell, internals, evaporators and condensers of a second column are not necessary. Further, the control and maintenance efforts are drastically reduced.

- Dividing wall columns are an alternative to multi-column circuits, which reduces investment and operation costs. As a rule of thumb, investment costs are reduced by minimim 20 - 30 % and operations costs by minimum 25 %.